Every day, millions of people in the U.S. take generic drugs instead of brand-name ones. It’s not because they’re cheaper alone - though they are - but because the FDA guarantees they work just as well. If you’ve ever wondered how a pill that costs a fraction of the brand version can possibly do the same job, here’s how it actually works.

Same Active Ingredient, Same Effect

The FDA doesn’t just accept that a generic drug is "close enough." It demands exact matching of the active ingredient. That means the chemical compound responsible for the drug’s effect - whether it’s atorvastatin for cholesterol or metformin for diabetes - must be identical in both the brand and the generic. No shortcuts. No substitutions. The FDA requires manufacturers to prove this through detailed chemical analysis before even starting clinical testing. The strength of the drug is also tightly controlled. A 10mg tablet of a generic must contain between 9.5mg and 10.5mg of the active ingredient. That’s a ±5% tolerance, and every batch is tested to meet it. This isn’t guesswork. It’s measured with lab-grade instruments that detect parts per million. If a batch falls outside that range, the entire lot gets rejected.Bioequivalence: The Real Test

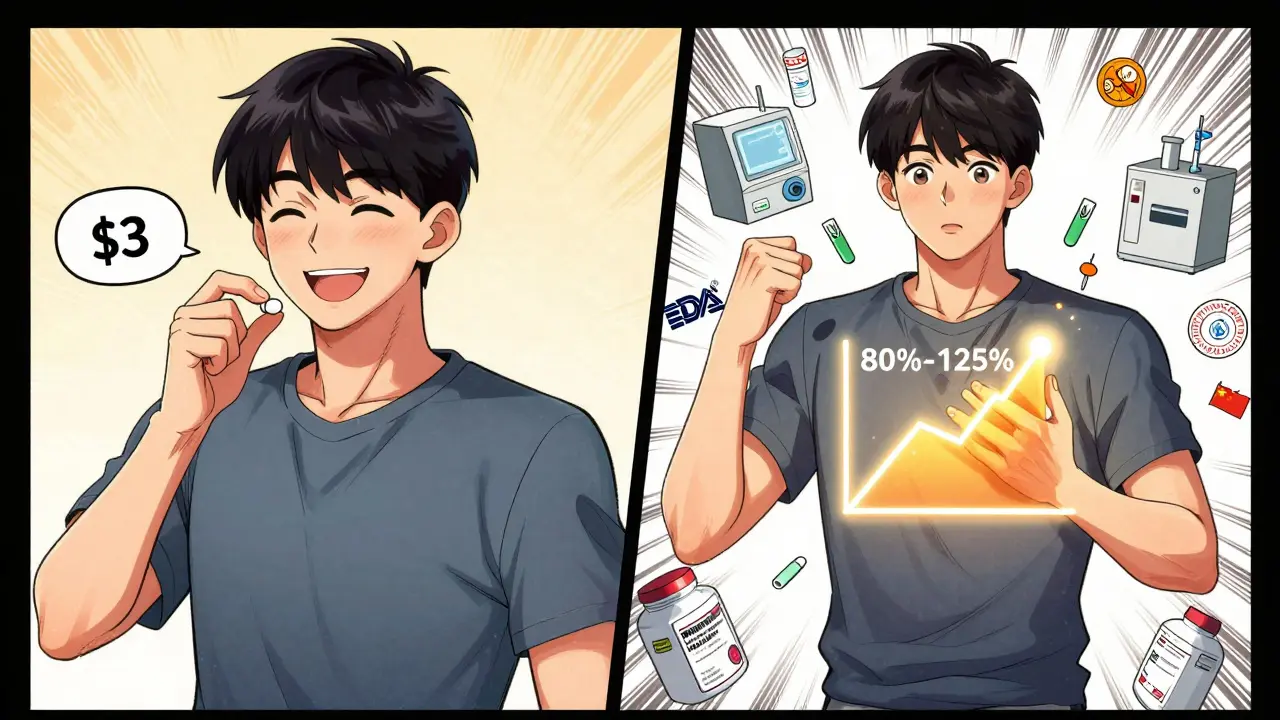

Here’s where most people get confused. You might think, "If the ingredient is the same, why test anything else?" The answer is absorption. A drug isn’t useful if it doesn’t get into your bloodstream the right way. That’s where bioequivalence comes in. The FDA requires generic manufacturers to prove their product is absorbed into the blood at the same rate and to the same extent as the brand-name version. This is measured using two key numbers: AUC (area under the curve) and Cmax (peak concentration). For approval, the generic’s results must fall within 80% to 125% of the brand’s. That’s not a wide margin - it’s a narrow, science-based window designed to catch even small differences. These tests are done in clinical studies with 24 to 36 healthy volunteers. They take the brand drug one day, the generic the next, under strict conditions - fasting or fed, depending on the drug. Blood samples are taken every 15 to 30 minutes for hours. The data is analyzed using statistical models. If the 90% confidence interval for both AUC and Cmax doesn’t land inside that 80-125% range, the application gets rejected.Manufacturing Standards Are Just as Strict

A drug isn’t safe just because the ingredient works. How it’s made matters too. The FDA inspects every manufacturing facility - whether it’s in the U.S., India, or China - using the same rules as for brand-name drugs. These are called Current Good Manufacturing Practices (cGMP), laid out in 21 CFR Parts 210 and 211. Every step - from mixing powders to filling capsules - must be validated. Machines are calibrated. Temperatures are logged. Batches are tested for purity, strength, and uniformity. The FDA’s own standard, USP <905>, requires that each tablet in a batch contains 85% to 115% of the labeled amount. If one out of 100 pills is off, the whole batch fails. Even inactive ingredients - like fillers, dyes, or coatings - are tracked. The FDA maintains an Inactive Ingredient Database with safe limits for over 500 substances. A generic can use different excipients than the brand, but only if they’re approved and within safe concentrations. That’s why some people notice a different taste or pill size - the non-active parts changed, not the medicine inside.

The ANDA Process: Faster, But Not Easy

Generic drug makers don’t repeat the 10-year clinical trials that brand companies do. Instead, they file an Abbreviated New Drug Application (ANDA). That’s why generics are cheaper - they avoid the massive upfront research costs. But "abbreviated" doesn’t mean easy. An ANDA can run 30,000 to 50,000 pages long. It includes everything from the chemistry of the active ingredient to the stability of the final product under heat and humidity. The FDA’s Office of Generic Drugs reviews each one. In 2022, they approved 777 ANDAs. About 35% of initial submissions got a "Refuse to File" letter because they were incomplete or missing key data. The average review time is 10 months. But if there’s a problem - say, the bioequivalence study was flawed or the factory didn’t pass inspection - the FDA issues a Complete Response Letter. Common reasons: inadequate testing (28%), manufacturing issues (22%), or labeling errors (18%). Fixing those can add six to twelve months to the timeline.What About Complex Drugs?

Not all drugs are created equal. Some, like inhalers, injectable emulsions, or topical creams, are harder to copy. Their effect depends not just on the ingredient, but on how it’s delivered. For these, the FDA has stricter rules. In 2022, 45% of rejections for complex generics came from failure to prove equivalence in delivery. For example, a generic EpiPen must deliver the same amount of epinephrine in the same way as the brand - not just in the bloodstream, but in the right tissue at the right speed. The FDA created a Complex Generic Drug Product Initiative to tackle these. They’ve issued 27 new guidance documents since 2023, each tailored to a specific complex product. Even for drugs with narrow therapeutic indexes - like warfarin or levothyroxine - the FDA requires tighter bioequivalence limits: 90% to 111%. That’s because tiny changes in blood levels can cause serious side effects. These are listed in the FDA’s official Narrow Therapeutic Index Drug Product List.

Real-World Evidence: Do They Really Work?

Some patients worry they’ll feel different on a generic. A 2023 IQVIA study of 15 million patients found no difference in outcomes between brand and generic versions of 20 common drugs, including blood pressure and diabetes meds. Adherence was actually 3.2% higher with generics - likely because they cost less. The FDA’s own adverse event database shows generic drugs report side effects at almost the same rate as brand-name drugs: 1.7 per million prescriptions versus 1.6. That’s not a meaningful difference. Still, some pharmacists report patients saying they feel "off" after switching - especially with neurological or thyroid meds. The FDA acknowledges this. But their data shows these reports rarely match up with lab results. In most cases, it’s a placebo effect, anxiety about the switch, or changes in inactive ingredients affecting absorption slightly.Who Makes These Drugs?

The U.S. generic market is dominated by big players like Teva, Viatris, and Sandoz. But 55% of approvals go to smaller manufacturers. That’s by design. The FDA launched its Generic Drug Competition Action Plan in 2017 to fight shortages and price gouging. More competitors mean lower prices and more reliable supply. In 2023, over 14,000 generic drugs were approved in the U.S. That’s more than 90% of all prescriptions filled. And they save the system $313 billion a year. The FDA’s goal isn’t just to approve generics - it’s to make sure they’re safe, effective, and available when patients need them.What’s Next?

The FDA is preparing for a wave of new generics as big-name drugs lose patent protection. Drugs like Humira and Enbrel are expected to open up to competition in the next few years. That could mean $260 billion in brand-name sales shifting to generics by 2028. To handle the volume, the FDA’s GDUFA III program is pushing to cut review times to 8 months for standard applications and 6 months for priority ones. They’re also testing faster review paths for cancer generics and planning a new approval system for biosimilars - generic versions of biologic drugs - by 2025. The bottom line? The system isn’t perfect. But it’s built on science, not speculation. Every generic you take has been reviewed, tested, inspected, and approved under the same standards as the brand. If you’re worried about switching, talk to your doctor or pharmacist. But don’t assume a generic is less effective - the FDA’s system is designed to make sure it’s not.Are generic drugs as safe as brand-name drugs?

Yes. Generic drugs must meet the same safety and quality standards as brand-name drugs. The FDA requires identical active ingredients, same strength, same dosage form, and same manufacturing practices. Every facility - whether making brand or generic - is inspected under the same rules. Adverse event reports show no meaningful difference in safety between the two.

Why do some people say generics don’t work as well?

Some patients report feeling different after switching, especially with drugs for thyroid, epilepsy, or blood thinning. But clinical studies show these differences are rarely real. Often, it’s due to changes in inactive ingredients, anxiety about the switch, or natural variations in chronic conditions. The FDA tracks these reports and requires tighter bioequivalence standards for drugs where small changes matter.

How long does it take for a generic to get approved?

The FDA aims to review a standard ANDA in 10 months. But many applications are incomplete or flawed on first submission. About 35% get a "Refuse to File" letter. If issues are found later - like problems with the bioequivalence study or manufacturing - it can take 6 to 12 months longer to fix them. Complex drugs, like inhalers or injectables, often take longer due to additional testing requirements.

Can a generic drug have different ingredients than the brand?

Yes, but only the inactive ingredients - like fillers, dyes, or coatings. The active ingredient must be identical. The FDA maintains a database of safe limits for over 500 inactive ingredients. Manufacturers can use different ones, but they must stay within approved concentrations. That’s why generics may look or taste different, but they still deliver the same medicine.

Are all generic drugs made in the U.S.?

No. About 80% of generic drug ingredients are manufactured overseas, mostly in India and China. But every facility - no matter where it is - must pass the same FDA inspection as U.S.-based plants. The FDA conducts over 3,500 inspections a year worldwide. If a factory fails, its products are blocked from entering the U.S. market.

How does the FDA prevent shortages of generic drugs?

The FDA has a program to identify drugs at risk of shortage and gives them priority review. In 2023, 47 drugs received this designation, leading to 12 approvals in under 6 months - half the normal time. The agency also encourages competition by fast-tracking generics for drugs with few manufacturers. This helps prevent price spikes and supply gaps.

10 Comments

Write a comment

More Articles

Ampicillin and biofilms: Can it help break down bacterial communities?

In my latest research, I came across an interesting topic about Ampicillin and its potential role in breaking down bacterial communities known as biofilms. Biofilms are notorious for their resistance to antibiotics, making infections difficult to treat. Ampicillin, a widely used antibiotic, has shown some promise in disrupting these communities. Studies have suggested that it could weaken the biofilm structure, making it easier for other antibiotics to penetrate and eliminate the bacteria. It's fascinating to think that a common antibiotic like Ampicillin might be the key to tackling these stubborn bacterial communities!

Tadacip (Tadalafil) vs Other ED Pills: Complete Comparison Guide

A thorough comparison of Tadacip (tadalafil) with sildenafil, vardenafil, avanafil, and generic tadalafil, covering onset, duration, side effects, cost and how to choose the best ED pill.

Warfarin Food Interactions: Complete Food List and Guidelines for Stable INR Control

Learn which foods affect warfarin, how to maintain stable INR levels, and what to avoid - including cranberry juice, grapefruit, and vitamin K-rich greens. Practical, evidence-based guidelines for safe long-term use.

Raja P

December 24, 2025 AT 02:54Man, I never realized how much goes into making a generic pill. Back home in India, we make a ton of these, and yeah, the labs are legit. FDA inspections? We get those too - same paperwork, same stress. It’s wild how strict they are about even the dyes in the coating. I’ve seen factories get shut down over a 0.3% impurity. No joke.